Novel solutions for complex material challenges

First time exhibitor Styron showed off its broad range of plastics solutions for various markets (Automotive, Electrical and Lighting, Medical, Packaging, Home Appliances, Consumer Electronics and Building and Construction.) at the K, carrying the theme, “Powering Ideas. Delivering the Future”, which the firms says centres on “generating powerful solutions that contribute to the success of (Styron’s) customers”.

“As a global player, we are close to our customers and able to respond quickly to their technical and operational needs,” says Martin Pugh, Senior Vice President and Business President, Plastics. “We intend to continue to focus on growth opportunities in our strategic markets and evolve to meet our customers’ business needs in the areas of cost-efficiency, sustainability, energy efficiency, lightweighting and improved performance. At Styron, we are passionate about the ability to work with our customers to innovate - not by just developing new resins, but by developing tailored solutions that address challenges they face. This is what our K-theme ‘Powering ideas. Delivering the Future’, is all about, ” he quips.

Styron’s product highlights of the show included engineering resins ranging from polypropylene compounds and LGF PP, ABS, PC/ABS to Polycarbonate resins for automotive interiors, exteriors and structural applications. From best-in-class scratch resistance and light-weighting, to high heat resistance and low VOC levels, the resins offer outstanding durability and high-end aesthetics. In addition, Styron’s team will present the first commercialisation of VELVEX 5250 following a two-year collaboration with Autocomponent, a leading manufacturer and exporter of automotive components. As a result of this collaboration, GAZelle Next platform benefits from interior parts with improved soft touch, scratch resistance, low gloss while meeting the need for cost-efficiency in raw material usage along with a positive evaluation of VELVEX 5250 on the Priora Face lifting platform.

Within the electrical and lighting market sector, a key area of Styron participation is the development-phase of electrical charging stations and helping our customers to meet the new set of EU regulatory requirements. Moreover, it says that its products play an integral role in the production and performance of smart meter applications within Europe. For the lighting market, Styron offers a range of advanced polycarbonate resins to help enable more energy efficient bulbs that perform effectively and meet safety standards, while offering design freedom to lighting designers and manufacturers. At K 2013, Styron’s Electrical & Lighting team will highlight advances in light-diffusion technology through products like CALIBRE 302V-6 LD, as well as CALIBRE 320UV, which can function as a UV-protective cap layer that allows for excellent light diffusion and transmission and improved aesthetics for LED backlit signage. Products such as EMERGE IR PC and PC/ABS resins have been tailor-made by our R&D specialists to achieve a superior balance of mechanical and electrical properties, good dimensional stability, flame retardancy, and processability.

For the medical sector, polycarbonate compounds/ blends, and ABS from Styron are used in everything from surgical staplers and endoscopic surgery tools, to dialysis machines and equipment used in rehabilitation medical devices. These medical-grade resins can offer an important combination of properties - such as strength, toughness, heat tolerance, clarity, and biocompatibility. During the show, the Styron team will be on hand to discuss several resins for equipment housings such as EMERGE PC/ABS 7700 Advanced Resin - a robust solution for many housing powered device applications designed with improved UL94 and thermal stability performance. The EMERGE PC/PET 9000 series will also be showcased, which encompasses impact modified blends of polycarbonate and semi-crystalline polyester. This series offers outstanding chemical resistance, exceptional low temperature impact and facilitated processability, including thermoformability. Styron’s innovative resins for single/multiple use devices also will be presented, such as CALIBRE and MEGARAD Polycarbonate Resins that can be sterilised and disinfected by ultraviolet radiation, ensuring that patients are not exposed to microorganisms during their treatment. Styron will highlight these grades that offer medical device manufacturers additional options to meet stringent requirements, while ensuring patient safety and cost efficiency.

The consume electronic sector, from mobile/tablet enclosures, laptop housings, printer enclosures and internal parts, to many associated electronic accessories such as power adaptors, will be covered by EMERGE Advanced PC resins that will allow downgauging in laptop enclosures without sacrificing stiffness. Styron will feature several grades of polycarbonate compounds and blends with Post-Consumer Recycle (PCR) content of up to 50%. With PCR polycarbonate, recycled plastics have a second life in a variety of consumer electronics applications such as smartphones, tablets, notebooks and printers.

Last but not the least, the packaging sector, specifically the PS bottling production will be served by Styron through its value chain partner, Sacmi. The machine manufacturer featured Styron’s resins on its K stand in one of its new machines using Compression Blow Forming (CBF) for PS bottle production. CBF is an innovative production process that consists of extrusion, compression moulding and forming. This game changing technology for dairy bottle production was developed by Sacmi and utilises Styron’s A-TECH 1200, a high-impact polystyrene (HIPS) resin based on patented technology. According to Sacmi, bottle manufacturers are usually faced with the dilemma of having to trade off one key property for another, such as toughness or stiffness and flow, or gloss.

However, with the A-TECH 1200, an all-rounder, with excellent performance results across a wide range of mechanical performance tests , compromises are unnecessary.

Flame retardants for high-temperature thermoplastics

Clariant, a leading speciality chemicals firm, showcased at the event its cutting-edge, efficient phosphinate flame retardants with new tailor made synergistic formulations for thermoplastics used in demanding environments. Exolit OP 1400 (TP) for polyamides and Exolit OP 1260 (TP) for polyesters offer the plastics industry new opportunities to improve both fire safety and processing and mechanical performance at the same time.

Clariant’s new synergistic formulations overcome the traditional challenge for flame retardants posed by the high processing temperatures of polyamides and the high temperatures where engineering thermoplastic polyesters are used. Both Exolit OP 1400 (TP) and Exolit OP 1260 (TP) achieve UL 94V-0 classification down to 0.4mm thickness and CTI values of 600 volt.

“The New Exolit OP 1400 (TP) and OP 1260 (TP) build on the capabilities of Clariant’s existing OP grades already widely used in polyamides and polyesters, mainly in reinforced compounds,” said Michael Grosskopf, Head of Business Unit Additives, Clariant.

“As synergistic formulations they go a step further, responding to market and regulatory demands for more environmentally-friendly solutions that can be tailored to the fire protection and particular performance challenges of engineering thermoplastics.”

Exolit OP 1400 (TP) provides enhanced thermal stability to polyamides, which makes it especially suitable for high processing temperatures and compounds that are injection molded into complex cavities. This avoids problems such as polymer degradation, formation of decomposition products and discoloration, which can occur during processing in case of insufficient thermal stability of the flame retardant additive

Its superior thermal stability extends the application range of flame retarded polyamides in hot and humid environments and creates productivity benefits during processing. Compared to the former Exolit OP grades for polyamides, the throughput of compounding machines can be increased, making the processing steps more efficient.

The synergistic blend Exolit OP 1260 (TP) provides a new flame retardancy solution to manufacturers looking to use halogen free reinforced polybutylene terephthalate (PBT) in applications such as insulating parts in the electrical and electronic (E&E) industry. Reinforced PBT has a lower melting point and heat distortion temperature than its commonly used counterpart polyethylene terephthalate (PET) but is a better electrical insulator. The strength and stiffness of reinforced PBT also enables its use in thinner wall sections. This generates both efficiency advantages and helps to miniaturize end-products, delivering more opportunities for manufacturers and OEMs.

Exolit OP 1260 (TP) addresses fire safety and the performance requirements of PBT for specific applications without the need for an additional flame retardant additive. It enhances melt flow and improves the mechanical properties of PBT used in injection molding, achieving UL 94 V-0 even at 0.4mm thickness.

Robust polymer stablilisers

Songwon Industrial , the second largest manufacturer of polymer stabilisers in the world, likewise launched its SONGXTEND product line at K.

The SONGXTEND line offers innovative stabilisation packages that solve a number of key issues encountered during processing, conversion and the end-use life cycle of polyolefins.

Currently, SONGXTEND products are commercially available and the product range will be expanded continuously to meet emerging customer needs, says Songwon.

According to the firm, SONGXTEND 1101 and SONGXTEND 1102 general purpose stabilisation packages allow polypropylene producers and processors to maintain high temperature manufacturing while safeguarding the desired properties of the polymer. At the same time SONGXTEND stabilisers will assist in avoiding degradation and discoloration under severe processing conditions.

Stability is assured from reactor to extruder where high heat and shear are often encountered. The stabilisation package continues to be effective during conversion and end-use applications. As such, molders and converters can maintain efficient processing speeds and elevated temperatures.

SONGXTEND 2121 (reduces sulphur by 60% while still maintaining high thermal stability), SONGXTEND 2122 (offers an optimized cost/performance balance by reducing sulphur by 30% as well as maintaining the thermal stability levels of SONGXTEND 2121), and SONGXTEND 2123 (100% sulphur free to reduce possible odor distraction in car interiors to the absolute minimum combined with a heat stability performance) stabilisation packages are designed for the automotive industry and are tailored to address fogging and odor issues in car interiors. Songwon adds that these stabilisers reduce VOC emissions and improve organoleptic properties by either eliminating or reducing undesirable odors that negatively impact car interiors.

Thomas Schmutz, Songwon’s Global Technical Service Director, stated, “In line with our promise to continue extending our product portfolio and to push the boundaries of stabilisation to meet specific industry needs, we are pleased to announce the introduction of SONGXTEND stabilisers. This new product development has been driven by our understanding of customer needs.

SONGXTEND stabilisation packages perform beyond classic state-of-the-art systems. SONGXTEND stabilisers now open the processing window to encompass a wider range of conditions and settings as well as meeting critical targets related to fogging and odor. Innovation is a key component of Songwon’s strategy. Our solutions are designed to be much more effective than common stabiliser concepts which allow reduced concentrations of additives in the resin or compound.”

Integrated TPUs for adhesives

Lubrizol featured its integrated portfolio of Pearlstick and Pearlbond thermoplastic polyurethanes (TPUs) for adhesives and binders (including integrated Merquinsa legacy technology) for the first time at K.

Arnau Pano, European Business Director, Lubrizol Engineered Polymers and LifeScience Polymers, says, "Merquinsa’s acquisition by Lubrizol enhances the capabilities of Lubrizol Engineered Polymers to meet the needs of its global customers through innovative technologies and an expanded product portfolio. The addition of low melting point Pearlbond and Pearlstick TPU, to the high melting point Estane product offering, uniquely positions Lubrizol to satisfy customers’ melting range needs across a wide crystallisation range.”

The added product lines include Pearlstick TPU for adhesives, as well as Pearlbond TPU used as an additive to increase crystallisation speed in PUR (reactive polyurethane) hot melts, and also used in heat sealable fabrics for technical textiles and in the footwear industry. This combined adhesive product line can be applied in a variety of end-uses: automotive, furniture, wood structures, apparel, medical garments, footwear and construction.

In addition to its wide-range of TPUs for adhesives, Lubrizol also displayed its new, high-performance specialty Estane TPU grades for the industrial, electronics and sports and recreation markets.

Meanwhile, at the TPE Conference organised by Smithers Rapra during the Düsseldorf exhibition, Lubrizol presented its new aliphatic TPU for

Under its Estane Engineered Polymers platform, Lubrizol has expanded its already broad portfolio of engineered polymer solutions with the integration of Merquinsa legacy aliphatic and bio-based thermoplastic polyurethanes (TPUs), commercialised under Pearlcoat, Pearlthane and Pearlthane ECO. At Rapra’s TPE 2013 conference, Maria Josep Riba, Applications R&D Elastomers EMEAI Manager, presented the expanded aliphatic portfolio, which also included new and improved moulding grades. These aliphatic innovations, according to Lubrizol sprung from the increasing demand for light colours or transparency in several technical and fashion applications.

A wide variety of end-use applications from the automotive, electronics and industrial sectors require new elastomers to combine the outstanding properties of TPU (such as good abrasion and scratch resistance), while offering excellent colour fastness upon UV exposure. New aliphatic Estane resins have been developed to answer these specific needs and provide high performing features like balanced impact and mechanical properties, better thermal stability and chemical resistance, easier processing conditions and outstanding flexibility at lower temperatures, down to -56°C.

Alternative solutions to metals

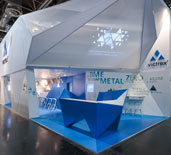

UK_headquartered Victrex Polymer Solutions put forth its message at the K: “Metal replacement – Durability – Lightweight construction”.

Victrex , with its high performing plastics and helping customers turn challenging application requirements into added value with solutions based on VICTREX PEEK, presented three current topics via taglines to their customers.

“It’s time to scrap metals.” According to Stephen Dougherty,Strategic Marketing Director of Victrex, there are at least three good reasons to replace metals with Victrex polymers: Increased efficiency, simplified design and reduced costs. “Low weight and simpler processing as compared with metals enables us to offer decisive advantages to processors and OEMs with our high-performance thermoplastics,” he explained. And he cites gear wheel applications as an example.

“Engineers were able to increase the efficiency of a mass balance system for automotive engines by 9% merely because a gear wheel made of VICTREX PEEK was 68% lighter, could be designed differently, and so ultimately made it possible to reduce the moment of inertia by nearly 80%. In addition, the reduction of noise, vibration, and harshness was lowered by 3dB, which is equivalent to a 50% noise level reduction for the human ear, “ he said.

In aircraft construction, the key considerations in the design of each newly developed component include not only fuel efficiency, but also time-savings in assembly and maintenance, he added. “Using design-optimised clips made of VICTREX PEEK, the installation of electrical harnesses is 30% faster than with the conventional fasteners made of aluminium used up until now: that clearly represents a key sales argument,” Dougherty said.

“The road to no wear.” The three things that many manufacturers want from their components and system solutions are long service life, low wear and minimal maintenance requirements. And selecting the right materials can make all the difference, according to Victrex, in light of the second tagline. For the experts at Victrex, the same principles essentially apply no matter if it involves small filling bushings used to produce fruit gum candy or components used in offshore oil production applications. “Reliability and safety are of huge importance in both industries. Of course the food industry and the energy sector have different standards. That’s why we offer the individual application development support our customers need – from basic design to the finished product – based on the PEEK expertise we’ve acquired over the course of the past 35 years,” explained Rainer Müller, Commercial Manager Europe for Victrex.

The service life of the PEEK solution for food production, for example, is up to 200% longer than the brass bushings used previously. “Because changing the filling bushings is very difficult and time-consuming, the filling machines have to be taken out of service for almost a whole day each time, so this saves a lot of time and money,” said Müller.

”Lift off with less.” In aircraft construction, every single gramme counts, Victrex said, referring to how lightweight becomes a significant gauge for a supplier to be counted as reliable in the industry. “The reason for this is simple: the cost of fuel ultimately represents 40% of an airline’s total operating costs. As we all well know, its consumption rises and falls with weight,” explained Harald Hedderich, Aerospace Strategic Marketing Manager for Victrex Polymer Solutions.

OEMs and suppliers have already specified many applications with VICTREX PEEK, in order to help reduce costs and emissions through enhanced performance as a result of their solutions, now and in the future. “The same principle applies in the automotive industry,” added Jürgen Reinert, Global Automotive Strategy Manager. “Statutory regulations are getting tighter and tighter. Energy efficiency as well as safety must increase and driving comfort must be improved at the same time, “ he concluded.

(PRA)