Also, download this story from the electronic issue here

Indian extrusion and thermoforming machinery maker Rajoo Engineers has brought its technologies globally, with exports accounting for over 50% of its sales and it has installations in 56 countries. Rajoo was founded in 1986 by the late Chandrakant N. Doshi. His entrepreneurial legacy and forward thinking lives on through the company, which was built on team work. PRA interviewed Khushboo Chandrakant Doshi to learn more about the company's efforts and focus this year.

Rajkot-based Rajoo says it offers the widest range of mono and multi-layer blown film lines (up to seven layers), an impressive range of sheet lines (up to five layers), water quenched downward extrusion lines (up to two layers), lines for PE and PS foamed film and sheets (for various standard and special applications).

It also offers end-to-end thermoforming solutions, including newer additions to the product portfolio that are the non-woven fabric and drip irrigation lines.

While having expanded its reach to overseas markets, export demand has reduced from the European countries and thus, last year, the company’s focus was more on the domestic market and the other side of the globe.

Thus, the Asian and African markets buffered Rajoo's efforts from the impacts of market shifts in Europe, where it has already gained a customer base. In Europe, some of the powerhouse economies, especially the export-driven ones, are being drilled down by poor fiscal performance, according to industry analysts.

Rajoo's business approach to this is being able to accept that the only thing constant in the industry is change. Moreover, along with the acceptance, it adapts to the varying regional needs, and for which, the company says that it constantly seeks avenues to provide the right combination of a diversified product mix so as to create the right solution to suit local needs.

PRA :

Rajoo introduced a few innovations in 2014: the Dripex and Multifoil Lite. Please provide an overview of the lines introduced last year.

Khushboo :

We have understood well the needs for drip irrigation wherein the Flat Drip System offers tremendous advantages over the Round Drip. These systems consume less material, are light weight; easy to ship, store and install, thus benefiting the agriculture and horticulture industries.

Based on this, thus, we introduced the Flat Drip System and that too successfully. For the critical assemblies of this system, we are partnering with Mopline of Israel.

The position of leadership is further reinforced as Rajoo today is the only company in India with highest number of successful installations and has obtained repeat business for Flat Drip Irrigation pipe plants.

With a position of market leadership in high-end multi-layer lines, and to address changing market needs, we introduced the Multifoil Lite, a two-extruder/three-layer (A-B-A type) blown film line, empowering its customers to remain aggressive in the highly competitive bag making industry, which is plagued with increasing costs of raw materials. Processors are now able to use high calcium carbonate-based filler in the middle layer, sandwiched between thin skin layers of virgin material, thus reducing film costs without sacrificing on surface properties.

While the machine is designed to run with A-B-A configuration, it’s specially designed cross head provides the flexibility to run A-B-B and A-A-B configurations as well, another first for the industry from Rajoo! With A-B-B, it is possible to produce lamination grade film and also for liquid packaging. It is really a versatile solution.

PRA :

Overall, how do you assess 2014 for your company in terms of market growth and sales?

:

Khushboo :

We are targeting a top line growth of around 12% for the financial year 2014/15. Our bottom line will increase correspondingly due to our focus on cost reduction and economies of scale.

Being a multi-product company, we are less affected by the vagaries of volatility in the economy, but we are not untouched by it. Our new joint venture with sheet extrusion equipment and thermoforming machinery maker MEAF of Holland will also begin to bear fruit in the coming years.

PRA :

With regards to the MEAF joint venture, how will this collaboration further improve the packaging sector in India?

Khushboo :

The process of giving light to the joint venture is underway. This joint venture is targeting the semi-rigid packaging sector. Demand for disposable containers is increasing exponentially in India and this needs energy efficient extrusion technology, coupled with automation in thermoforming solutions.

Equipment from European sources is not economically viable for a low-cost economy like India and we firmly believe, we have the most cost effective solution for this industry.

PRA :

Could you tell us about the technology collaboration Rajoo has with Hosokawa Alpine, and how it has helped the Indian plastics industry?

Khushboo :

Over a period of time, we have not only benefited from the technology but also improved the quality standards of our products. We are also supplying many parts to Alpine now.

Today, Indian processors need high quality with consistency to cater to various brand owners. We are able to offer cost effective blown film equipment in the “Balanced Solution” format where all the hot parts are supplied by Hosokawa Alpine, automation is also sourced from Europe while the rest of the assemblies are from Rajoo. This does give a competitive advantage to our customers, when compared to fully European lines.

:

PRA :

What about the pipe technology collaboration with Bausano & Figli?

Khushboo :

With operations commencing in 2011, RBE (Rajoo Bausano Extrusion) has already supplied India’s highest diameter pipe plant to a customer in Malawi and also CPVC pipe plants in India and Bangladesh.

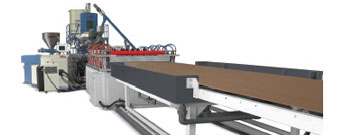

RBE has also successfully acquired the technology of WPC (Wood Plastics Composite) and PVC foam board sheet from Bausano and demonstrated the same in a recently concluded open house in India. RBE has become the only supplier of WPC lines in India and that too with a capability of processing 70% wood in the product.

PRA :

Chinese machine manufacturers have enjoyed a huge following in countries where lower cost of machines is vital, and quality or output are secondary considerations. What do you think of this?

Khushboo :

Now, processors have begun to understand the differences. Low cost, low technology equipment in the long run will be detrimental to a business. It has not been difficult for us to convince processors.

Energy is the second biggest component in processing after raw material costs and our machines and technology are far more energy efficient compared to the machines from other Asian countries. We, thus, see no issues in being competitive from an overall perspective.

PRA :

Technology advanced machines are implied to be more expensive. Can you tell us how Rajoo is able to meld quality, innovation and affordability?

Khushboo :

It is not always true that technologyadvanced machines are more expensive. What is important is to be able to choose the most appropriate technology for the specific applications and this is where Rajoo scores.

Many times it has been seen that several features in the machine are never utilised but the processor continues to pay for it.

Rajoo’s strength lies in first understanding the processor’s needs, configuring the most appropriate technology and then making it cost effective. It is a unique blend of customisation and affordability. Needless to say that overheads and overall costs of production at Rajoo are much lower. This benefit of cost savings is passed on to customers.

PRA :

Were there any challenges in 2014 that your company encountered and successfully dealt with?

Khushboo :

The biggest challenge has been the sharp drop in polymer prices that has resulted in high volatility. In such circumstances, cash flow of processors is affected and the first casualty is always investment in capital goods.

We encountered this effectively by being alert of the situation, reaching out to new markets, both geographically and with product introductions. Though this made a huge demand on our resources, we managed it well.

Managing change is the biggest challenge for any business entity and we have been able to manage it.

PRA :

Will there be any new innovations at Plastindia 2015?

Khushboo :

Being innovation-driven, Rajoo has an impressive track record of technology firsts in different product categories.

Yes, Rajoo will showcase the industry’s first-ever equipment, and the first at a Plastindia show. We are displaying the most awaited product for producing disposable plastic containers – a fully automatic Tilting-Mould Thermoformer with online stacker to meet the demand of counting, stacking and packing. This solution will not only provide ease of operation but increase the production rate and reduce the requirement of scarcely available labour.

We are also displaying a fully automated five-layer blown film line with elevated air ring for producing barrier films used for edible oil packaging and lamination grade films. While we have displayed such plants in the past, the elevated air ring for higher output levels will be a novelty.

PRA :

What sector(s) do you foresee will stand out this year, and will generate demand for your equipment/solutions?

Khushboo :

We believe that the need of flexible and semi flexible packaging will keep increasing to meet the demand of the growing retail sectors.

Furthermore, with the focus by the current government for infrastructure and agriculture, for which we have solutions now, there will also be further demand for our solutions in these industries.

PRA :

Will there be new collaborations with other companies this year?

Khushboo :

At Rajoo, our quest for introducing cost effective technologies to the developing world is going to continue. While on the one hand, we will continue to evaluate new technologies, we will also ramp up our capacities by investing in new machines and upgrading infrastructure.

PRA :

What is Rajoo's secret to its staying power in the industry?

Khushboo :

Constant technology upgrading, appropriate customisation and efficient after-sales service are some of the ingredients of Rajoo’s success. We operate as a customer’s partner in progress and not as a machinery supplier.

What is unique about Rajoo is that we are able to offer affordable advanced technology systems without compromising on high-end features required by manufacturers, such as ease of operation, improved productivity, reduced requirement for manpower, and less material use, to cite a few features.