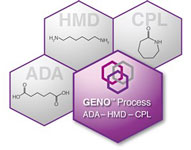

US technology firm Genomatica will use nylon intermediates – including hexamethylenediamine, caprolactam and adipic acid (HMD, CPL and ADA) – in its development for biobased production of these intermediates, which it will then license to major firms in the nylon value chain. These three chemicals, with a total market of over US$18 billion/year, are used primarily in the production of nylon 6 and nylon 6,6.

Genomatica has been building a comprehensive set of nylon programme assets over the last few years. It builds on a large body of intellectual property (IP), which includes but is not limited to eight issued US patents and numerous pending applications worldwide, as well as trade secrets that include engineered strains, with some of the IP developed internally and some from a recent IP acquisition.

A number of the concepts described by Genomatica's patent filings have been validated in experimental proofs of concept, demonstrating feasibility. These include the successful demonstration of certain metabolic pathways; production of certain nylon intermediates in various microorganisms; and efficient methods to produce and recover certain nylon intermediates from the fermentation. Genomatica's nylon intermediates program follows commercialisation and licensing of its GENO BDO process, and strong progress with its butadiene program, which has gained over US$100 million in industry support, with Italy-based Versalis and Brazilian chemicals maker Braskem as anchor partners.

Nylon intermediates programme targets important advantages Genomatica is focused on developing biobased processes that deliver the exact same chemicals as those made with petroleum-based feedstocks, along with better overall economics and greater sustainability. For nylon intermediates, Genomatica's processes are intended to provide on-purpose alternatives to current processes while avoiding the price volatility or limited supply sources of current raw materials such as benzene or adiponitrile.

Genomatica's technology also has the potential to avoid unwanted byproducts and waste streams characteristic of many current processes. Its integrated biotechnology platform, which combines process engineering, predictive computer models, and experimental biotechnology, has been key to its confidence in the feasibility of delivering commercially-advantaged processes in this field. Development of commercial processes for nylon intermediates is expected to take several years, and follow a sequence of technical, partnership, scale-up and commercialisation milestones.

As with its butadiene programme, Genomatica is inviting leaders in the nylon value chain to join as development partners for its nylon intermediates program. Development partners have the opportunity to engage throughout the program, influence priorities and gain early access to the resulting process technology. Genomatica believes that such access can provide important time-to-market and competitive advantage to program sponsors.

"Genomatica's team, broad IP portfolio and integrated biotechnology platform enable us to develop processes for multiple high-volume chemicals," said Christophe Schilling, CEO of Genomatica. "

Genomatica’s GENO BDO process for producing butanediol (BDO) has been licensed by BASF and by Novamont; BASF has announced its first commercial production; and multiple large chemical firms have publicly validated quality and/or described commercialisation plans, including Invista (for its well-known Lycra), DSM, Lanxess, Toray, and Far Eastern New Century.

(PRA)