For more download this story from the electronic issue here

According to the Italian trade association Assocomaplast, the Italian plastics and rubber machinery shows positive signs, mainly due to exports, even given the fact that Italy is in the throes of an economic downturn. It is against this backdrop that the triennially-held plastics show Plast 2015, will be held in Milan, Italy, from 5-9 May, in conjunction with the inaugural week of Expo 2015. Whether it is the attraction of being able to attend the Milan Expo, the number of exhibitors at PlastMilan is 3.9% higher at 1,200, compared to PlastMilan three years ago.

In the first nine months of 2014, exports of Italian machinery reached EUR1.89 billion, compared to EUR1.82 billion in the corresponding period in 2013. Expectations for the current year are marked by optimism. This positive sentiment is reflected in the six pavilions at Plast 2015.

"Beyond the numbers," emphasises Promaplast Managing Director Mario Maggiani, "it is important to note how foreign exhibitors continue to believe in Plast, expanding the same spaces reserved in 2012. Plast is not only holding its ground, but gaining more, as confirmed by the increase in new exhibitors, both Italian and foreign, who have made the decision, for the first time, to exhibit at the fair."

Compounding/Masterbatch

- Following the acquisition of Iride Colors in 2013, compounding solutions provider Mesgo went on to acquire Guzzetti Master and 3A MCOM, thus opening up to new markets for pigments, additives, filled masterbatches and thermoplastic compounds. Last year, Mesgo Asia was set up in Turkey. With the recent acquisitions, expansion and a new R&D centre, Mesgo says it is able to cater to the elastomers sector, supplying from thermoset to thermoplastics compounds.

- During the course of the last 40 years, Colmec says it has achieved a leading position within the European market for the manufacture of extrusion lines and compounding solutions for rubber and silicone. It recently opened a new technology centre.

- Maris considers itself a leader in the production of complete extrusion lines, with co-rotating twin-screw extruders and self-cleaning modular screws, suitable for the compounding and granulation of materials.

- German exhibitor Pallmann will be highlighting its PMM 300 PolyGrinder system for the pulverisation of thermoplastics under ambient temperature, without adding cooling agents like liquid nitrogen. The system is suited for processing large volumes up to 650 kg/hour, for masterbatch, compounding and rotomoulding operations. Material is discharged into a cyclone and collected in bags, containers or can be conveyed to the next production step.

Extrusion/Converting/Recycling Machinery

- Bandera will show a three-layer blown film co-extrusion line for the production of film for flexible technical packaging. This line is suitable for the extrusion of symmetrical structure film for lamination and flexible packaging. In addition, it will have an open house at its headquarters in Busto Arsizio, where it will be testing a new seven-layer co-extrusion blown film line, mainly designed to process PET/PP and PLA rigid film. Both lines will be running 1.2/1.4 tonnes/hour, with a net web width of 1,500 mm. Thicknesses range from 0.14-1.6 mm. These lines are pre-equipped with systems capable of processing physical foam PET, as well.

- With 50 years of experience, Omipa offers complete extrusion and co-extrusion lines for hollow profiles up to 3,000 mm width and thicknesses from 2-40 mm. There is also a special five-layer co-extrusion line. For standard quality sheet production, its lines offer thicknesses from 1-30 mm and widths up to 3,000 mm. In co-extruded sheet and foil of up to seven layers and more, the lines offer thicknesses from 0.15-10 mm (or more) and widths up to 3,000 mm. It also has lines for foil wound on reels, with thicknesses from 0.1-3 mm and widths up to 3,000 mm; as well as lines for high optical quality sheet and foil with thicknesses from 0.15-30 mm.

- Amut Group will have under its booth the newly acquired Amut Dolci Bielloni, with a shuttle bus service to its facility where it will present two cast stretch film lines, one producing hand and automatic rolls (2,000 mm, seven layers) and the other, jumbos (1,500 mm, five layers). In recycling, a DLB60 de-labeller, with 6,000 kg/hour of PET bottle capacity, will be shown. Installed at the start of a washing line, the dry pre-cleaning system removes the full-body shrink sleeve labels from PET bottles.

- For wood composites, it has developed the BA92 counter-rotating twin-screw extruder with a direct extrusion system (output from 250-600 kg/hour).

- Further, Amut will also show its TEAT 7 for r-PVC pipes with a diameter up to 710 mm.

- With 40% of the lines it delivered worldwide last year of the POD (polyolefin dedicated) type, Macchi will show this line. The ability to use all the five extruders, the company says, has resulted in a number of successes, particularly in collation shrink film manufacture, with a market volume of over 1 million tonnes, and in the flexible packaging industry. The line will feature new web handling devices and take off units, equipped with special solutions including the use of air-porous roller, built with sintering technology, special release and rubber coatings, necessary for the handling of tacky films.

- Macchi is also installing a fourth machining centre at its facility, capable of handling dies of up to 2,500 mm diameter and will enlarge the current three/fivelayer range of IBC heads required for agricultural greenhouse films. To cater to this, Macchi will enlarge its second factory by 6,000 sq m.

- Elba, which has been manufacturing automatic highspeed pouch and bag maker machines since 1956, provides side seal, stand-up and side gusset pouch maker machines, wicket bag maker machines, high barrier shrink film bag machines, retail bag maker machines. Other equipment in its range include pet food pouch maker machines, STEB maker machines, medical/pharmaceutical pouch and bag maker machines.

- Tosh is presenting, in addition to its flexible and high-speed series, the Logica Cartesio multi-colour pad printing centres that are numerically controlled. With these new machines, Tosh says it is able to impose the pad printing process in applications where it had been excluded due to limitations in mechanical construction, confirming that pad printing is an advantageous technique amongst the various decorating processes.

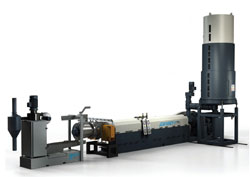

- Recycling equipment maker Gamma Meccanica will roll out the latest version of its GM50 Compac, the GM65, which can be loaded directly onto the container without the need to disassemble the Compac and extruder due to the integrated design. The line also has a TDA 3.4 pelletiser. The new generation lines offer improved insulation and feeding zones, with enhanced cooling and screws to allow for higher outputs. The electrical control panel is installed on the support base to prevent errors and the need to disconnect the cables for transportation and re-wiring during assembly, hence reducing the installation time.

For more download this story from the electronic issue here