Building Industry: Smart materials hit home

Advanced material technology builds the foundation for the new era of smart building and home structures, says Angelica Buan in this report.

The building and construction sector accounted for 36% of final energy use and 39% of energy and process-related CO2 emissions in 2018, 11% of which resulted from manufacturing building materials and products such as steel, cement and glass, according to a 2019 report by the Integrated Environmental Assessment (IEA) of the UN Environment Programme. That is why, energy efficiency in buildings can help in emissions reduction that is necessary for mitigating climate change.

Not only does an energy efficient environment save up on energy costs, it can also promote comfort and health of users and dwellers.

Materials used in structures can also help in increasing the energy efficiency in buildings. It is for this reason that the smart materials market is poised to advance in the coming years, in view of the changing global safety, efficiency and sustainability standards.

Smart materials are like living parts of a smart structure – they can sense their environment and respond accordingly to such conditions or stimuli as pressure, temperature, electric/magnetic field, mechanical/physical stress, pH, and so on. Smart materials have mechanisms that defy the limitations that conventional materials, such as concrete, metal or wood , and help optimise energy use of the space.

Supercapacitor with bricks

Energy savings in homes can be as simple as unplugging electric appliances or switching off lighting fixtures to reduce electricity consumption. But what if we can harness electricity directly from the wall?

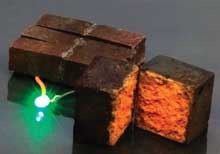

In today’s material technology advancement, it is no longer a far-fetched idea. Researchers at Washington University in St. Louis, Missouri, have developed smart bricks that can store energy. According to the paper presented by the team , led by Julio M. D’Arcy, Assistant Professor of Chemistry, and published in Nature Communications, the smart brick can store enough energy to power emergency lighting or sensors that could be embedded inside the walls of a house.

For starters, bricks offer a porous network and a very strong material. In their study, the team filled the maze-like pores inside the brick with chemical vapour. The reaction was a plastic nanofibre coating, known as Pedot, as well as causing the bricks to turn from reddish orange to a dark blue. Due to the multitude of pores, more of the brick’s interior surface was coated. That enhanced the brick’s ability to store energy and turned it into a supercapacitor, which isn’t able to store as much energy but can more powerfully and quickly discharge electricity.

In their research, the team stacked about 60 bricks, which were able to store enough energy to power a 3W light bulb for nearly one hour; and they recharged within 15 minutes. While more research is needed, the team believes this proof of concept may one day result in walls that are able to store energy, enough to power bigger devices like laptops.

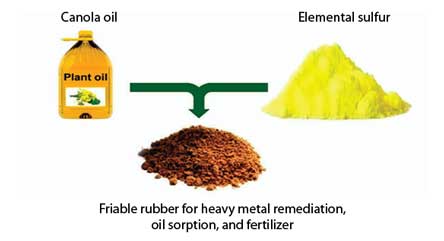

Meanwhile, sustainable bricks were the focus of the study of a team of Australian scientists from Flinders University. They experimented on a rubber polymer to develop a type of green brick that is made from recycled PVC, waste plant fibres or sand.

The rubber polymer is made from sulphur and canola oil, and can be compressed and heated with fillers to create construction materials that is deemed to replace non-recyclable construction materials, says a new paper published in ChemEurJ.

The powdered rubber can be potentially used for tubing, rubber coatings or bumpers; or compressed, heated then mixed with other fillers to form entirely new composites, including more sustainable building blocks, concrete replacement or insulation. The team, led by Flinders PhD Nic Lundquist, said that adding that the rubber particles also can be first used to purify water and then repurposed into a rubber mat or tubing.

The novel recycling method (called reactive compression moulding), as well as the new composites, according to Lundquist, are an important step forward in making sustainable construction materials, and an additional method of recycling PVC or carbon fibre.

Smart opportunity for future window technology

Windows are one of the most important parts of a dwelling space, and at the same time, a key factor in preserving its energy efficiency. Being that windows are responsible for heat loss or maintaining the coolness of the house, incorrect orientation or design can affect the comfort of the dweller. Glass in windows, being a conductor of heat, can contribute to the amount of sunlight coming through the home and can even significantly increase its cooling load.

A smart window developed by researchers from Korea Institute of Energy Research (KIER) can automatically adjust the amount of sunlight entering the room by changing the colour of window depends on the intensity of sunlight. It does this without the use of an external power supply.

Read more...

(PRA) Subscribe to Get the Latest Updates from PRA Please click here

©2020 Plastics and Rubber Asia. All rights reserved.

©2020 Plastics and Rubber Asia. All rights reserved.

Home Terms & Conditions Privacy Policy Webmail Site Map About Us