Green tie-ups: AmSty/Agilyx on to 2nd jv PS facility in US; Sumitomo Chemical awards Toyo contract for waste-derived ethanol/ethylene plant in Japan

AmSty, the largest polystyrene (PS) producer in the Americas, and recycler Agilyx Corporation, a wholly owned subsidiary of Agilyx AS, are to explore the development of a jointly owned advanced recycling facility. The initial scope of this project will be a 50 to 100 tonnes/day advanced recycling facility located at AmSty's Styrene production facility in St. James, Louisiana. The facility will be a next generation expansion of Agilyx advanced recycling technology already in use at the parties' Regenyx joint venture operating in Tigard, Oregon, where post-use PS products are converted back into virgin-equivalent styrene monomer. A feasibility study for the project is under way, with a timeline for construction and commissioning to be announced as progress continues.

Feedstock for this collaboration would be accessed via Cyclyx, Agilyx's feedstock management company. AmSty is a founding member of the Cyclyx consortium. The Cyclyx platform encompasses an integrated set of innovations including chemical characterization of plastics, predictive modelling of feed sources to product pathways, custom feedstock recipes, and customized supply chains to deliver waste plastic feedstocks appropriate for recycling pathways.

"Polystyrene is an ideal material for the future of recycling," said Dr. Randy Pogue, President/CEO of AmSty. "Not only can polystyrene products offer sustainability advantages where less material is required (e.g., a polystyrene foam cup is 95% air), but polystyrene is particularly advantageous for advanced recycling because it can be "unzipped" back to its original liquid form, styrene monomer, using 40% less energy than other polymers. As the global plastics industry moves toward circular recycling to build value and grow access, polystyrene becomes very attractive as a first mover with its inherent conversion advantages. AmSty is committed to keeping polystyrene products out of landfills through circular recycling. We are excited to expand our relationship with Agilyx in this new project to accelerate progress."

"Development of this technology has picked up over the past decade, and it is time to reach a larger scale," said Tim Stedman, CEO of Agilyx. "We have been operating Regenyx with AmSty since 2019 and are pleased to expand our relationship toward a much larger facility at St. James. Joining AmSty as a co-investor underlines our commitment to accelerating the implementation of Agilyx advanced recycling technology and our licensing model. We believe that our technology will significantly increase the availability of recycled content for producers."

Meanwhile in other news, Toyo Engineering Corporation has been awarded a contract for a project to construct an ethylene pilot plant, using waste-derived ethanol as raw material, planned by Sumitomo Chemical. at its Chiba Works, Japan, for completion by 2022.

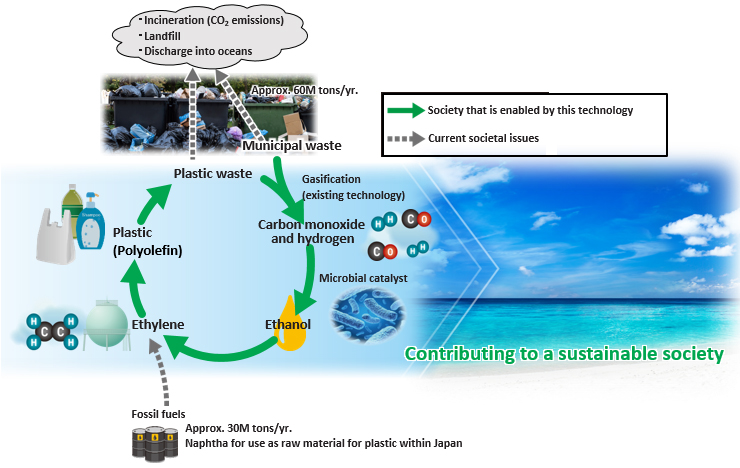

Sumitomo has established a cooperative relationship with Sekisui Chemical. for the implementation of the technology to manufacture polyolefin using waste as raw material and will begin pilot production of the high pure ethylene, which is the raw material for polyolefin, using waste-derived ethanol to be produced by Sekisui from the fiscal year 2022.

Toya adds that it has worked with Sumitomo from the basic design of the plant and is currently carrying out the detail engineering, procurement, and construction under the EPC lump-sum contract, aiming to start demonstration operation of the plant for a short period.

Sekisui developed the technology in 2017 in cooperation with a US company LanzaTech Inc. This technology enables gasification of combustible waste accumulated at waste disposal facilities into carbon monoxide and hydrogen without the need for waste separation, and converts these gases into ethanol using a microbial catalyst, which obviates the need for heat or pressure.

Meanwhile, Sumitomo has developed and accumulated, over many years in the petrochemicals field, proprietary technology and know-how, and is now developing technology to manufacture polyolefin from ethylene using waste-derived ethanol as a raw material.

(PRA)

Subscribe to Get the Latest Updates from PRA Please click here

©2021 Plastics and Rubber Asia. All rights reserved.

©2020 Plastics and Rubber Asia. All rights reserved.

Home Terms & Conditions Privacy Policy Webmail Site Map About Us