Chinaplas 2021: advancing circularity via various approaches

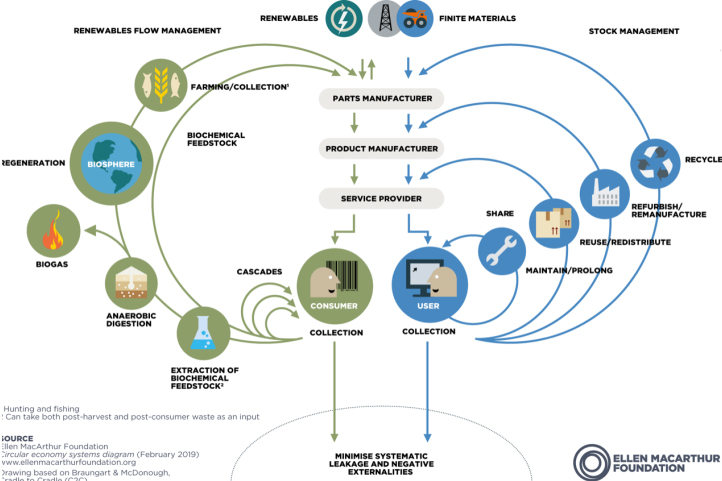

A circular economy is one that is restorative and regenerative by design. It takes “a systemic approach to economic development that is designed to benefit businesses, society, and the environment,” says the Ellen MacArthur Foundation, the UK-based organization widely seen as the leading proponent for the concept. In contrast to the “take-make-waste” linear model, notes EMF, a circular economy aims to gradually decouple growth from the consumption of finite resources. It is based on three key principles: design out waste and pollution, keep products and materials in use and regenerate natural systems.

The plastics and rubber industries are increasingly focusing on at least some of these principles as they strive to meet increasingly stringent environmental regulations, reduce overall material use, find ways to effectively recycle and reuse products and materials, and develop more environmentally friendly materials such as those that are bio-based rather than petrochemical-based. Following is just a tiny sampling of some of the types of actions currently taking place.

PolyREC takes flight

In mid-March four of Europe's major plastics industry associations -PlasticsEurope, Petcore Europe, VinylPlus, and Plastics Recyclers Europe - announced they have teamed up on an initiative called PolyREC. This concept aims to use a shared data-collection system called RecoTrace to monitor, verify, and report plastics recycling volumes and uptake data in Europe. This, the participants say, will allow those involved to provide traceability, transparency, and trust in recycled materials along the entire plastics value chain.

“Setting up mechanisms that evidence progress in driving plastic circularity in a transparent manner is a must if we are to meet the EU targets,” said PRE President Ton Emans. PolyREC plans to use a RecoTrace system that has been built on the Recovinyl platform, which VinylPlus developed and has been using for 20 years to collect recycling data. VinylPlus Managing Director Brigitte Dero stated that the circularity of plastics is a key opportunity to enhance the overall sustainability of plastics products.

In the Loop

One of the higher-profile efforts to promote reuse in the consumer packaged goods arena is being driven by Loop – a circular shopping platform started in 2019 by New Jersey-based entrepreneur Tom Szaky, who also heads the initiative’s parent company, Terracycle. Launched initially in the northeastern U.S. and in Paris, the Loop program has now expanded to the UK, Canada, and across all 48 contiguous U.S. states, with plans to begin operating in Germany, Australia and Japan this year.

The system uses a parcel-delivery service to ship a variety of food, household cleaning, and personal-care products in a reusable and collapsible, padded container called the Loop tote. The products are dispensed from reusable containers, which are returned in the same container when empty. Some call this “the milkman model,” referring to the old days when milk was delivered to your doorstep in glass bottles, which later were collected, cleaned and reused.

“Loop,” says Szaky, “is an engine for CPGs [consumer packaged goods companies] to shift from disposable products those consumers own to durable ones they borrow.” So, with the brand owner actually owning their product’s packaging, they have the incentive to devise attractive, durable, cleanable packages that can be reused at least 100 times. This leads to the design of refillable containers, with the aim of eliminating the single-use, disposable packages that dominate retail shelves (and landfills) today.

Loop has many major organizations as partners – such as Danone, Procter & Gamble, Unilever and retails chains such as Carrefour Group – with dozens of leading brands participating. Terracycle, which operates in 20 countries and focuses on recycling difficult-to-recycle products, has ambitious plans to keep expanding Loop globally.

Bio-friendly straws using Smart Plastic

Smart Plastic Technologies LLC of Wheeling, Illinois, has taken a different path. It has developed its SPTek ECLIPSE bio-assimilation technology for use in polyolefins such as polyethylene and polypropylene to allow them to totally degrade.

Using this patent-pending technology, Smart Plastic has just introduced polypropylene drinking straws that it says “will truly and completely biodegrade, resulting in nothing more than CO2, water and biomass. Following its guaranteed life, the straw will bio-assimilate in marine, terrestrial and landfill environments within 12–42 months, resulting in zero microplastics.”

It is estimated that consumers use as many as 500 million plastic straws in the U.S. alone every day, prompting companies such as Starbucks to ban them at their stores. That works out to about 182.5 billion straws a year. Each straw weighs only about 0.4 g, or equivalent to roughly 73,000 metrics tons of plastic straws per year. While the overall environmental impact is not huge, in the scheme of things, every bit of waste reduction helps.

More importantly, Smart Plastic President and Chief Operating Officer Jay Tapp says he sees many potential applications not only for its SPTek ECLIPSE technology, but for several other sustainable additives that he believes will contribute to a new generation of eco-friendly plastics and dramatically reduce plastic waste.

A circular guidebook for EE&A

German materials supplier Covestro and Chinese consultancy REnato lab are jointly launching a “Circular Design Guidebook” for the electrical, electronic and household appliance (EE&A) industry. With circularity gaining importance in that sector, the firms note that more and more manufacturers are talking about their sustainability goals, in particular about an increased use of recycled materials in their end products.

"The key to solving the problem of material waste is to consider the end of product life in the initial design phase to facilitate recycling," said Lily Wang, Sr Vice President and Global Head of EE&A in Covestro's Polycarbonates segment. The book uses case studies and processes to explain material selection so that products meet sustainability and recyclability requirements. It also describes the resource constraints facing the industry, supply chain-oriented thinking, relevant business models, and provides a basic introduction to the circular economy.

From household trash to resin

Israel's UBQ Materials said March 22 that it has just earned a pair of ISO quality certifications for its “climate-positive” material derived from landfill-destined household waste. The company's patented technology converts landfill-destined household waste into a sustainable, bio-based, cost-competitive thermoplastic material called UBQ™. The firm says the resulting resin can fit seamlessly into current manufacturing practices and be used to make products for a variety of sectors.

For every ton of UBQ material produced, the company says, nearly 12 tons of CO2-equivalent emissions are averted, “preventing significant greenhouse gas emissions from landfills where municipal waste would otherwise decompose and release methane and other toxic gases into the environment.”

Enabling 100% PCR packaging

Avient Corp. has launched a new masterbatch made with post-consumer recycled (PCR) polyolefin as a carrier resin that “aims to make production with 100% PCR an industrial reality.” The product, called Rejoin PCR Masterbatch, can enable a bottle or part to be manufactured entirely from PCR, the Ohio-based company said.

Until now, it noted, masterbatch generally has been made using virgin material as a carrier resin. This means that at typical let-down ratios, the finished product would contain 3% to 5% non-recycled plastic. This development will help major consumer goods companies to meet their sustainability goals of 100% PCR polyolefin packaging, according to Bob Lee, Avient’s marketing director, Color& Additives Asia.

Many different eco-options

There are numerous ways to strive for circularity, and it’s clear that no single approach alone can achieve the ambitious aims laid out by the Ellen MacArthur Foundation and others focused on eliminating plastics waste.

But EMF remains optimistic, stating: “Our economy is currently locked into a system that favors the linear model of production and consumption. However, this lock-in is weakening under the pressure of several powerful disruptive trends. We must take advantage of this favourable alignment of economic, technological, and social factors in order to accelerate the transition to a circular economy.

“Circularity,” the nonprofit group says, “is making inroads into the linear economy and has moved beyond the proof of concept; the challenge we face now is to mainstream the circular economy, and bring it to scale.”

Among the resources that EMF offers to help brand owners and product designers along this journey is the Circular Design Guide and the Circular Design Toolkit. (Press Release)

(PRA)

Subscribe to Get the Latest Updates from PRA Please click here

©2021 Plastics and Rubber Asia. All rights reserved.

©2020 Plastics and Rubber Asia. All rights reserved.

Home Terms & Conditions Privacy Policy Webmail Site Map About Us