PRA Chinese

Rubber Journal Asia Injection Moulding Asia Energy, Oil & Gas Asia

VISIT OUR OTHER SITES:

PRA Chinese

Rubber Journal Asia

Injection Moulding Asia

Energy, Oil & Gas Asia

Partners collaborate in closed loop recycling of PS in Canada

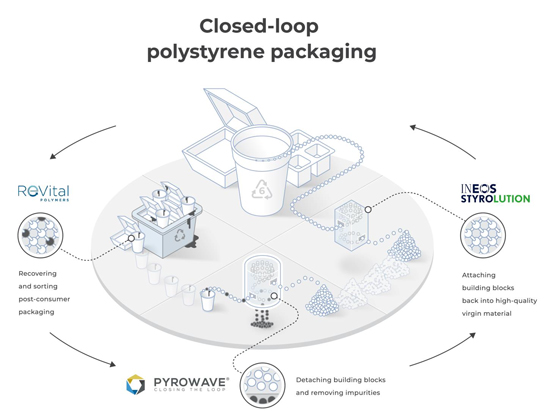

Three companies involved with post-consumer packaging recovery – ReVital Polymers, Pyrowave and Ineos Styrolution – have entered into a partnership to recycle polystyrene (PS) packaging collected in consumer curbside and depot recycling systems as well as other sources such as restaurants, offices, schools and universities. This was made known at the recent G7 Ministerial Meeting on Working Together on Climate Change, Oceans and Clean Energy,

The collaboration says it will use advanced recycling technology pioneered by Pyrowave that will close the loop by recycling single-serve PS packaging and utilising recycled PS in the manufacturing of new products and packaging.

This Canadian solution will not only reduce the amount of PS packaging going to landfill, but will also address the global problem of plastic pollution in marine environments, say the partners.

PS is mostly known for its use in foam and rigid packaging, containers, cups and utensils commonly used for food and beverage delivery in supermarkets and take-out food service. By enabling this ground-breaking recycling chain, ReVital, Pyrowave and Ineow Styrolution will change the way post-consumer polystyrene packaging is recycled in an integrated, restorative and regenerative manner that maintains the material’s highest utility and value within a circular economy.

ReVital Polymers Inc., located in Sarnia, Ontario, is a member of the Circular Polymers Group, and a North American leader in processing post-consumer plastics. ReVital will install Pyrowave’s Catalytic Microwave Depolymerisation (CMD) technology as part of its plastics recycling process. Pyrowave’s award-winning microwave machine will convert ReVital’s sorted post-consumer polystyrene packaging to a liquid that contains plastic building blocks, called monomers, which will then be used by Ineos.

Styrenics maker Ineos will process the material from ReVital and Pyrowave in a final step to return it to virgin resin that can be made into any new PS application.

Pyrowave’s technology, the connecting link between the ReVital and Ineos, provides a process that makes PS infinitely recyclable even with colour additives and food residue.

“This is a game changer for consumers and for municipal and industrial, commercial and institutional recycling programs,” said Keith Bechard, Chief Commercial Officer at ReVital Polymers Inc. “Polystyrene packaging, regardless of colour, food residue or odours, can be successfully added to recycling programs. When these materials are shipped to ReVital, they will be recycled into a high-value material that closes the loop. For ReVital, this project is an opportunity to increase our range of acceptable feedstock, increase the recovery rate for residential and commercial recycling programs and increase our value proposition to customers.”

The three companies say they are committed to reducing the amount of plastic waste that ends up in landfill or contaminates the world’s waterways and oceans.

“Although we know there is a lot of polystyrene waste around us, surprisingly the challenge we face is the lack of available material because it is not properly recovered,” said Jocelyn Doucet, CEO of Pyrowave. “Pyrowave’s technology expands the range of acceptable polystyrene feedstock, making it possible to build a new value chain that links ReVital’s processing expertise with Ineos Styrolution’s global end-market capacity.”

The Pyrowave process is an example of how innovation in diversion technology goes beyond resin-to-resin recycling technologies.

The industry would like to send the signal that post-consumer PS can now be accepted through various collection programs. New technologies like Pyrowave are generating chemicals that are used by the manufacturers as feedstock to make new products and close the loop.

PS is versatile, inexpensive to produce, lightweight to transport and has a low carbon footprint compared to other packaging materials. The insulating properties of foam containers helps keep food at the desired temperature. But this material, like many other single-use packaging applications, suffers from poor recycling rates due to major limitations in recovering and utilizing soiled post-consumer containers.

The support from the public and private sector has been essential in developing Pyrowave’s technology and this project will continue to generate economical value and create and maintain jobs in the plastic recycling industry while strengthening the development of a more sustainable chemical industry. This project shows that innovative technologies developed in Canada can enable new circular business models, create new economical benefits and help solve a growing global environmental problem.

(PRA)Subscribe to Get the Latest Updates from PRA Please click here

Copyright (c) 2018 www.plasticsandrubberasia.com. All rights reserved.