TenCate Advanced Composites and German firm BASF have entered into a strategic alliance to cooperate on the development of thermoplastic composite materials suitable for high-volume vehicle production.

The main goal of this partnership is to offer car manufacturers custom-engineered solutionsfor high-performance composite structures, which enable this industry to further reduce weight and carbon dioxide emission.

TenCate Advanced Composites has a leading market position in continuous fibre reinforced thermoplastic composites with the TenCate Cetex product portfolio, currently mainly used for aircraft structures and interiors. At present new aircraft such as the Airbus A380, A350 and Boeing 787 are the main users of such material.

BASF will contribute its know-how in the production and formulation of thermoplastic resins in order to develop special variants of its Ultramid (PA), Ultradur (PBT) and Ultrason (PESU) product lines. TenCate Advanced Composites joins in with their expertise in composite manufacturing. Together both companies arededicated to automotive composite materials (UD-tapes, prepregs and laminates) based on these speciality resin systems.

Compared to metal parts, fibre-reinforced plastic composites can be 30 to 50% lighter, there by economising on fuel consumption. Due to the ease of thermoplastic processing, these advanced materials will dramatically reduce production cycle times, have no limitations in shelf life and can be recycled. Thus mass production becomes accessible.

Much experience has been built up over the last decades in connection with welding technologies to connect composites materials into complex structures and to integrate these components and structural parts into multi-material end-products. Target applications are semi-structural parts as well as primary structures in car bodies and chassis.

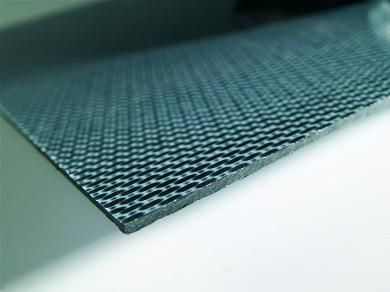

Thermoplastic laminates with continuous fibre reinforcement are woven or non-woven fabrics impregnated with resins and formed into sheets, which are extremely light yet very strong.

UD-tapes, another product class, make full use of the anisotropic nature of uni-directionally (UD) oriented impregnated fibres. In a second step, these semi-finished products can be formed into more complex parts and overmoulded by means of injection moulding. This combination results in components that are enhanced by a high degree of functional integration.

(PRA)