PRA Chinese

Rubber Journal Asia Injection Moulding Asia Energy, Oil & Gas Asia

VISIT OUR OTHER SITES:

PRA Chinese

Rubber Journal Asia

Injection Moulding Asia

Energy, Oil & Gas Asia

Waste: Shell turns plastic waste into chemicals; Ineos’s Italian plant to produce plastics from waste

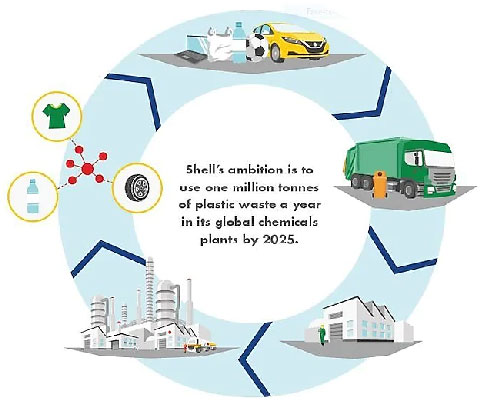

Oil company Shell says it has successfully made high-end chemicals using a liquid feedstock made from plastic waste through pyrolysis. The latter is considered a breakthrough for hard-to-recycle plastics and advances Shell's ambition to use 1 million tonnes/year of plastic waste in its global chemicals plants by 2025.

"This makes sense for the environment and our business," said Thomas Casparie, Executive Vice President of Shell's global chemicals business. "We want to take waste plastics that are tough to recycle by traditional methods and turn them back into chemicals – creating a circle. These chemicals will meet our customers' growing demands for high quality and sustainable products."

Atlanta-based Nexus Fuels recently supplied its first cargo of pyrolysis liquid to Shell's chemical plant in Norco, Louisiana, US, where it was made into chemicals that are the raw materials for everyday items. Shell is working with multiple companies who collect and transform plastic waste in order to scale this solution to industrial and profitable quantities across its chemicals plants – in Asia, Europe and North America.

Shell is a founding member of the Alliance to End Plastic Waste (AEPW). This not-for-profit organisation is bringing together top minds from across the plastics value chain (chemical and plastic manufacturers, consumer goods companies, retailers, converters and waste management companies) and partnering with the financial community, governments and civil society. The AEPW has committed US$1.5 billion over the next five years to help end plastic waste in the environment.

Shell says it is also working with its retail, business fuels and lubricants customers to help reduce, reuse and recycle plastic packaging.

Meanwhile in other news, Ineos has opened its new advanced polymer pilot plant in Rosignano, Italy, to develop and produce advanced products which will incorporate plastic waste diverted away from landfill or incineration. One example of the many products it will develop will include light weight car parts.

The plant supports a more sustainable and circular approach to polymer production, saving CO2 as well as directing plastic waste from landfill back into valuable polymer products. The new plant is part of Ineos’s global EUR100 million R&D programme, which supports Ineos customers globally.

Dr. Gerd Franken Chairman of Ineos Olefins & Polymers Europe and Chairman of Ineos Polyolefins Catalyst said: “This pilot plant will help to use more and more plastic waste for new high value polymers which is the very core of the circular economy. It demonstrates Ineos commitment to develop this technology to full commercial scale.”

Earlier this month Ineos Olefins & Polymers also announced the introduction of the Recycl-IN polymer range to its portfolio. The range contains up to 50% Post-Consumer Recycled plastic compounded with new virgin polymers.

(PRA)

Subscribe to Get the Latest Updates from PRA Please click here

©2019 Plastics and Rubber Asia. All rights reserved.

©2019 Plastics and Rubber Asia. All rights reserved.

Home Terms & Conditions Privacy Policy Webmail Site Map About Us