PRA Chinese

Rubber Journal Asia Injection Moulding Asia Energy, Oil & Gas Asia

VISIT OUR OTHER SITES:

PRA Chinese

Rubber Journal Asia

Injection Moulding Asia

Energy, Oil & Gas Asia

Davis-Standard: Encompassing market leadership

Also, download this story from the electronic issue here

Headquartered in Pawcatuck, Conn., Davis-Standard is a global leader in the design, development and distribution of extrusion and converting technology. Davis- Standard will promote the company’s equipment innovation and regional growth at Hall 9.2, Booth J41, during Chinaplas 2019 in Guangzhou, 21-24 May, alongside its subsidiaries Maillefer and Brampton Engineering. Davis-Standard will share information about its recent acquisitions, Suzhou facility expansion, DS Activ-Check system for continuous extruder monitoring, dsX flexpack ™ technology and stretch film capabilities; as well as exhibit a HPE- 100H, 1” 24:1 extruder.

Asia, still a hive of activity for manufacturing

The Asian region, led by economies successfully transitioning from middleincome to advance-economy standing, continues to propel the global economy as it represents more than 60% of world growth, according to the International Monetary Fund (IMF) assessment.

Despite the pervading tensed global financial and geopolitical conditions, the region wins over the obstacles of downside risks by tapping on its ample domestic markets, and reforming policies to further strengthen industries as well as the industrial capital.

The region is likewise on par with more mature economies in the west through increasing use of digitalisation and assimilating smart manufacturing into operations.

Even though IMF forecasts growth for Asia to fall slightly from 5.6% in 2018 to 5.4% in 2019, key industries, including the automotive, building and construction, electrical & electronics, medical devices, packaging and food and beverage, are sustaining the growth of the region.

The automotive industry is one such major industry that continues to shore up the region’s manufacturing industry. Demand for commercial vehicles continues to surge. Likewise, growth in construction activities in major markets is driving the demand for heavy trucks, buses and other commercial vehicles.

Likewise, the medical devices market is also flexing its might, poised to register a CAGR growth of 6.5% to US$167.2 billion from 2017-2026, according to Inkwood Research, while the Asian flexible packaging market is poised to reach a CAGR of 5.7% to US$6.7 billion from 2016-2024, according to a Transparency Market Research sector forecast, driven by growth and increasing disposable incomes.

The slowdown of China’s economy, and the challenges its manufacturing industry now faces against rising global protectionism, has diverted production to other manufacturing capable countries in the region.

Nonetheless, China remains a market ally for the region. The East Asian factory powerhouse continues to upscale its technological standards amid ever tightening competition in the global market. With its Made in China 2025 industry blueprint in place, the country drills on catching up with global peers in manufacturing technologies in the fields of automotive, aerospace, electronics, robotics, Artificial Intelligence (AI) and more.

Furthermore, China is among the global forerunners in machinery exports, as well as the world’s largest producer, consumer, and importer of machine tools.

According to data from the China Machinery Industry Federation, the country’s machinery exports grew 8.4% to US$406 billion in 2017, and continues to grow to current periods, due to structural reforms that have been effected, marked by tax incentives, and upgrades to hightech manufacturing with the integration of industrial robotics and AI.

Davis-Standard to highlight a bevy of products

It is against the above backdrop that Davis-Standard will

display its products/services at Chinaplas 2019. The US

company’s systems encompass over ten product lines

to support manufacturing applications and customers

within every major industry. This includes the agriculture,

automotive, construction, healthcare, energy, electronics,

food and beverage packaging, and retail industries,

among others.

to support manufacturing applications and customers

within every major industry. This includes the agriculture,

automotive, construction, healthcare, energy, electronics,

food and beverage packaging, and retail industries,

among others.

With more than 1,350 employees worldwide and a network of independent sales agents and suppliers in nearly every country, Davis-Standard is committed to engineering systems. The company has manufacturing and technical facilities in the US, Canada, China, Germany, Finland, Switzerland and the UK.

We find out more about the company through this interview with Sekaran Murugaiah, Vice-President Business Development Asia Pacific.

PRA: What technology/services will Davis-Standard be displaying at Chinaplas 2019?

We will promote our DS Activ-Check system for continuous extruder monitoring, dsX flex-pack™ technology and stretch film capabilities, and exhibit a HPE100 extruder.

The DS Activ-Check addresses demand for “smart” technology. Using DS Activ-Check, processors can take advantage of real-time preventative maintenance by providing early notifications of potential extruder failures. Machine operators are alerted to issues before they happen, preventing unnecessary downtime while also collecting valuable data. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling.

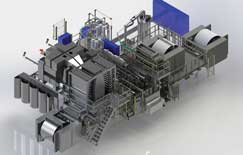

The latest dsX flex-pack™ model being promoted is the 300S. This single station extrusion and laminating line is designed specifically for the Asian flexible packaging market. It is a collaboration among Davis- Standard’s teams in the US, Germany and China, addressing the pricing, machine footprint, speeds and output, and shorter runs demanded by converters.

Davis-Standard is also engineering a tandem configuration of this machine called the dsX flex-pack™ 300T.

The dsX flexpack ™ 300S will be available for demonstration in Suzhou later this year.

For stretch film applications, Davis-Standard offers a stretch film line equipped with a DS S3 winder. The line offers a compact machine arrangement, ease of servicing, excellent profile control, consistent roll quality and an intuitive control package. It is engineered for producing thin films from 7.8 to 13 microns at high speeds. The side-by-side DS S3 overlapping winder is essential to this capability, enabling maximum slit widths for hand-wrap, machine-wrap and jumbo rolls. This winder also makes it possible for converters to support multiple market segments on one winder.

The model HPE 100 extruder being shown is an example of Davis-Standard’s performance engineering for versatility, long-term market value and an attractive return on investment. This extruder is designed for co-extrusion and multi-layer applications, and is available with a variety of DSB® feedscrew designs depending on applications.

Advantages include a small footprint, high-torque capacity to handle a variety of resins and a direct coupled motor. Models are available in 20-45 mm with L/D’s in 24:1 or 30:1. For added support, the extruder comes with a three-year warranty.

PRA: Are there new capabilities to be offered by Davis- Standard in Asia/China?

In addition to what is mentioned above, Davis-Standard recently acquired Thermoforming Systems, LLC (TSL), of Union Gap, Washington. With this addition, we are now able to offer in-line thermoforming technology for sheet and high-volume packaging applications.

PRA: Is Davis-Standard planning to expand its Suzhou facility with new capabilities?

Yes, Davis-Standard’s Suzhou location is expanding this year. The additional 3,251 sq-m facility near the existing shop in Suzhou will house control panel assembly and provide much-needed warehousing.

The addition reflects Davis-Standard’s strong

extrusion coating business and long-term strategy in

the region. Suzhou is also home to an R&D laboratory

that supports Asia’s medical market. This capability

has been an asset to customers, and an excellent

tool for supporting development of new resins and

biodegradable products.

extrusion coating business and long-term strategy in

the region. Suzhou is also home to an R&D laboratory

that supports Asia’s medical market. This capability

has been an asset to customers, and an excellent

tool for supporting development of new resins and

biodegradable products.

PRA: How have the Chinese/Asian markets fared for Davis-Standard?

There have been challenges with economic and trade uncertainties in China. However, we remain optimistic about the Chinese market and our business prospects there.

Meanwhile, plastic demand has continued in Asia, albeit at a slower rate. This has primarily been driven by global economic uncertainties, the slowdown in major economies like China, and uncertainties in the financial markets.

However, there are continuous and exciting growth prospects in the food packaging segment for sustainable solutions, innovative products and functionalities.

There will be challenges for single-use plastics in many countries, and the industry will need to effectively respond to this demand.

PRA: What aspects of Industry 4.0, offered by Davis- Standard, benefit businesses in China/Asia?

Industry 4.0 initiatives benefit everyone. Davis-Standard already offers excellent connectivity via our DS-eVUE and EPIC III® control systems. Connectivity is essential to making Industry 4.0 and the “smart factory” work. These controls are also compatible with our new DS Activ-Check system (mentioned above), which applies predictive maintenance analytics.

We place additional sensors on extruder components such as the gearbox and motor to monitor factors such as temperature, pressure and vibration. With Industry 4.0, we will be able to offer a complete solution that further digitises data collection and gives customers greater insight into improving and controlling processes. It is all about the ability to collect data that will help reduce waste, increase uptime and improve productivity.

PRA: Last year, Davis-Standard unveiled its new branding. Please provide a brief description of this new approach.

Our goal is to be the market leader in providing solutions that help customers better compete in today’s marketplace. We now have a brand that better speaks to that leadership.

Our new tag line – Where Your Ideas Take Shape – reflects this. We have been on an upward trajectory on a global scale, and now is the time for our brand to embody what we have become; and still intend to become.

Our aim is to work with customers in partnership to help them achieve a unique competitive advantage. We believe this can be achieved with technology that is tailored to customer needs as well as better ideas and holistic solutions. Our support services are central to this offering and our people are our most valuable asset. They are the heartbeat of the company; central to our approach and success.

PRA: After Davis-Standard added on Gloucester Engineering and Maillefer to its portfolio, last year it added on TSL and Brampton Engineering. What new opportunities do these new acquisitions provide Davis- Standard?

Each acquisition has been instrumental in being able to offer customers the best machinery in the industry. The acquisition of Brampton in 2018 augmented our multilayer film processing and winding technology for blown film applications. TSL (Thermoforming Systems LLC), also added in 2018, is the market leader in thermoforming equipment for high-volume packaging applications. TSL fits nicely with Davis-Standard’s continued growth in the packaging sector.

Maillefer, acquired in 2017, expanded the company’s wire and cable, pipe and tube equipment offering, and added facilities in Finland and Switzerland to better serve customers, including those in China.

The addition of Gloucester Engineering expanded our blown film capabilities and gave us one of the largest installed bases of equipment in the world.

These brands have made us stronger in terms of both equipment capabilities and aftermarket services.

PRA: Are there any updates or developments in downstream equipment?

We have ongoing efforts to further improve our winder and web handling system production and energy efficiencies.

PRA: Are there any upcoming plans for 2019 onward in terms of expansions, new technologies and facilities, R&D?

The dsX flex-pack™ 300S will be available for demonstration in Suzhou later this year.

We also continue with investments in R&D for extrusion and screw technology to support the development of new resins and biodegradable products, as well as energy efficiencies and reliability.

Visit Davis-Standard at Chinaplas 2019,

Hall 9.2, Booth J41

For more on the company visit:

www.davis-standard.com

Subscribe to Get the Latest Updates from PRA Please click here

©2018 Plastics and Rubber Asia. All rights reserved.

©2018 Plastics and Rubber Asia. All rights reserved.

Home Terms & Conditions Privacy Policy Webmail Site Map About Us