Bio tie-ups: Danimer/Pepsi for biofilms; Nestle/Danone for bioPET bottle by 2020

Biotechnology leader Danimer Scientific and global food and beverage company PepsiCo are teaming up to develop Danimer Scientifics’ biodegradable film resins to meet the sustainable flexible packaging requirements of PepsiCo’s global food and beverage business. The agreement builds on a long-standing relationship that has included the development of bio-based compostable packaging for PepsiCo’s snack brands and will facilitate the expansion of Danimer Scientifics’ Nodax PHA plant.

The agreement is a follow-up to PepsiCo’s 2025 sustainability agenda announced last year, which includes the intent to reduce greenhouse gas emissions across its value chain and design 100% of its packaging to be recoverable or recyclable. This collaboration is also expected to help expedite PepsiCo’s transition to packaging that is completely biodegradable for its snack food portfolio by incorporating Nodax PHA bioplastic into certain of its next-generation snacks packaging.

Nodax PHA is a naturally occurring biopolymer produced by microbial bacteria as they ferment organically sourced oils. Produced using renewable biomass, the PHA is both sustainably sourced and proven to be capable of replacing many short-term use petroleum-based plastics, for both performance and price. Danimer says its PHA received the first ever OK Marine Biodegradable certification from Vinçotte International, validating that the biopolymer safely biodegrades in salt water environments, leaving no toxins behind. It, thus, possesses seven Vinçotte certifications and statements of industrial and home compostability, biodegradability in anaerobic, soil, fresh water, and marine environments, and is bio-based. It is also FDA approved for food contact.

In other news, two of the world’s largest bottled water companies Nestlé Waters and Danone are partnering with Origin Materials, a US start-up based in California,

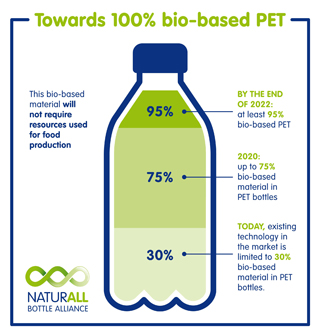

to develop a PET plastic bottle made from 100% sustainable and renewable resources. The project, known as the NaturALL Bottle Alliance, will use biomass feedstocks, such as previously used cardboard and sawdust, so it does not divert resources or land from food production for human or animal consumption. The technology represents a scientific breakthrough for the sector, says the companies, and the Alliance aims to make it available to the entire food and beverage industry.

to develop a PET plastic bottle made from 100% sustainable and renewable resources. The project, known as the NaturALL Bottle Alliance, will use biomass feedstocks, such as previously used cardboard and sawdust, so it does not divert resources or land from food production for human or animal consumption. The technology represents a scientific breakthrough for the sector, says the companies, and the Alliance aims to make it available to the entire food and beverage industry.

For decades, both Nestlé Waters and Danone have focused on developing innovative packaging solutions that are recyclable and made with renewable resources, as well as the promotion of recycling. After identifying the unique approach of Origin Materials separately, the two companies decided to team up to accelerate development of this promising technology.

Danone and Nestlé Waters are providing expertise and teams, as well as financial support, to help Origin Materials make this

technology available to the entire food and beverage industry in what they says will be record time.

technology available to the entire food and beverage industry in what they says will be record time.

This next-generation PET will be as light in weight, transparent, recyclable and protective of the product as today’s PET, while being better for the planet. The use of renewable feedstocks which do not divert resources or land from food production is the Alliance’s main focus area. The R&D will focus initially on cardboard, sawdust and wood chips but other biomass materials, such as rice hulls, straw and agricultural residue could be explored.

The NaturALL Bottle Alliance partners consider that everyone should benefit from this new material, so the technology will be accessible for the entire beverage industry. This unique approach demonstrates the allies’ commitment to open innovation and sustainable business.

Origin Materials has already produced samples of 80% bio-based PET in its pilot plant in Sacramento. Construction of a “pioneer plant” will begin in 2017, with production of the first samples of 60+% bio-based PET to start in 2018. The initial volume goal for this first step is to bring 5,000 tonnes of bio-based PET to the market.

NaturALL Bottle Alliance aims to develop the process for producing at least 75% bio-based PET plastic bottles at commercial scale as early as in 2020, scaling up to 95% in 2022. The partners will continue to conduct research to increase the level of bio-based content, with the objective of reaching 100%.

(PRA)Copyright (c) 2017 www.plasticsandrubberasia.com. All rights reserved.