PRA Chinese

Rubber Journal Asia Injection Moulding Asia Energy, Oil & Gas Asia

VISIT OUR OTHER SITES:

PRA Chinese

Rubber Journal Asia

Injection Moulding Asia

Energy, Oil & Gas Asia

K2019: Covestro hones in on CO2 technology and digitalisation

With materials manufacturer Covestro’s theme at K2019 in Düsseldorf in October on sustainability and digitalisation, it will be focusing on its strides made in its CO2 technology, in closing the carbon cycle.

CEO Markus Steilemann, speaking to journalists at a pre-K2019 event in Düsseldorf, said that the company has had successes but added, “it only makes sense if you have access to green energy.” He also added that resin materials can be made with carbon as a building block but this needs further development, with polycarbonate a likely material as an end resin from CO2, with different ways of bringing it back into the loop with the pyrolysis process.

“There are different technology approaches but we can’t do all of the technology in-house so we need to work with partners to achieve the closed loop concept.”

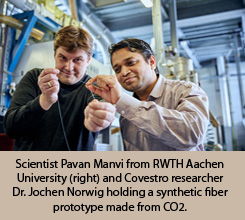

One of these is its cooperation with RWTH Aachen University and various textile manufacturers to produce elastic textile fibres from thermoplastic polyurethane with CO2. The intermediate product called cardyon is already used for the soft foam found in mattresses and the base layers of sports fields.

They can be used for stockings and medical textiles, for example, and might replace conventional elastic fibers based on crude oil.

Development of the method has been funded by the European Institute of Innovation and Technology (EIT). It will now be optimised as part of the “CO2Tex” project, which is to be funded by the German Federal Ministry of Education and Research (BMBF) so as to enable industrial production in the future. “CO2Tex” is part of “BioTex Future,” a project initiative of RWTH Aachen University.

“The partners are currently working on developing production to industrial scale and want to introduce a material cycle that is based on sustainable resources to the textile and garment industry,” added Steilemann.

Covestro says it also wants to take advantage of digitalisation and has started incorporating digital technologies and processes into production, the supply chain, R&D, at all customer contact points and in new business model development.

In terms of 5G, to build the infrastructure for it, Covestro is working together with Deutsche Telekom and the Umeå Institute of Design to develop material solutions for base stations, antennas and other system components.

Covestro is also working on a multi-layered film solution in conjunction with a new manufacturing process for the backs of smartphone bodies. Unlike conventional metal elements, these polycarbonate films are permeable to high-frequency radiation.

(PRA)Subscribe to Get the Latest Updates from PRA Please click here

©2018 Plastics and Rubber Asia. All rights reserved.

©2018 Plastics and Rubber Asia. All rights reserved.

Home Terms & Conditions Privacy Policy Webmail Site Map About Us