PRA Chinese

Rubber Journal Asia Injection Moulding Asia Energy, Oil & Gas Asia

VISIT OUR OTHER SITES:

PRA Chinese

Rubber Journal Asia

Injection Moulding Asia

Energy, Oil & Gas Asia

Davis-Standard introduces system for continuous extruder monitoring

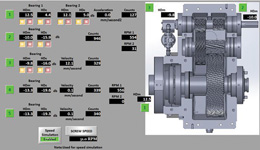

In response to the increased demand for “smart” technology, US-headquartered extrusion machinery company Davis-Standard has launched its DS Activ-Check system for continuous extruder monitoring. This technology was demonstrated at the NPE show in Florida earlier this year, and is an available option with Davis-Standard’s Integrator, Epic III and DS-eVue control systems.

Activ-Check enables processors to take advantage of real-time predictive maintenance by providing early notifications of potential extruder failures. Machine operators are alerted to issues before they happen, reducing unplanned downtime while also collecting valuable data. Users receive notifications via e-mail or text, and continuous monitoring of production machine status is available on smart devices and remote PCs. Key parameters monitored include extruder reducer, lubrication system, motor characteristics, the drive power unit, barrel heating and cooling.

The system is easy to operate due to overview screens that provide a quick reference of monitor points and trend windows, providing a graphic indication of measurements. Users can touch a location to view details, or use on-screen set-up for e-mail or text notifications. Vibration sensors on the extruder reducer provide data regarding the condition of the gears, bearings and lubrication system. The extruder motor is supplied with combination temperature sensors and vibration sensors. The reducer lubrication system (If provided), includes pressure, flow and temperature sensors to indicate system performance. Operators are also able to monitor key health indicator parameters in the drive power unit, providing an early indicator of potential power unit issues.

“The Activ-Check system provides much-needed data for processors to improve performance, including being able to plan production around scheduled maintenance activities,” said John Clemens, Director of Extrusion Controls at Davis-Standard.

He added, “Having the capability to monitor extrusion line variables such as mechanical and electrical system conditions is essential in order to bring products to market faster and minimise unplanned downtime. This technology will also allow customers to address a pending condition that could become a more serious issue in the future. All of this is valuable and much-needed knowledge to strengthen existing extrusion and converting processes.”

(PRA)Subscribe to Get the Latest Updates from PRA Please click here

Copyright (c) 2018 www.plasticsandrubberasia.com. All rights reserved.