Extrusion/Thermoforming Machinery

Also, download this story from the electronic issue here

Thermoforming Machinery

- During Chinaplas 2017, to be held from 16-19 May in Guangzhou, China, WM Thermoforming Machines will be promoting its FC series, vacuum and pressure thermoforming machines with steel rule cutting, FT series, in-mould trimming thermoforming machines with lower tilting platen, complete in-line plants as well as extrusion and thermoforming machines with direct recycling of the scraps, until the final product packaging.

- WM also recently introduced the second

generation small and flexible Twist 300. It

features in-mould trimming with lower 90 degree

tilting platen for thermoforming products with

a maximum negative depth of 120 mm. Another

new tilting machine, Twist 700, a pressure

forming machine with lower tilting platen without

mechanical cams, premiered at the K show in

Düsseldorf, Germany, last year.

tilting platen for thermoforming products with

a maximum negative depth of 120 mm. Another

new tilting machine, Twist 700, a pressure

forming machine with lower tilting platen without

mechanical cams, premiered at the K show in

Düsseldorf, Germany, last year. - Beside thermoforming machines, WM has its new N.EXT extruder with screw diameters of 45, 75 and 90 mm, 36 L/D ratio and output capacity from 450-900 kg/hour for PP material. Also, it will promote the B1400 Rim Rolling machine with improved product quality, widely used in the production of conical disposable cups made of PS, PP, APET or PLA.

- Italy’s Amut Group says it has recently

supplied to Indonesian packaging maker PT

Starplast Packaging Industry a complete in-line

thermoforming plant to produce disposable PP

cups for cold tea, with an output of 60 million cups/

month. Starplast supplies the Zegar brand, part

of 2Tang Group, one of the biggest producer of

mineral water and cold tea in Indonesia.

of 2Tang Group, one of the biggest producer of

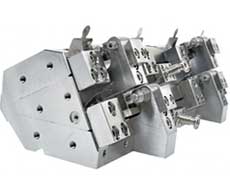

mineral water and cold tea in Indonesia. - The extrusion section is equipped with a threecomponents dosing system and an EA130 40 L/D Amut extruder with a capacity of 800 kg/hour using 50% regrind material in the thermoforming process. The improved calender with 500 mm rolls shaped for high stiffness complies with the product specifications of a PP foil with 1,200 micron-thickness. The line also includes the 70-tonne AMP 850-GP thermoforming machine, with forming and trimming in one station and tilting moveable lower platen. The 55-cavity mould has an area of 850 x 560 mm. Other features are a fully automated pick-up stacker and a grinder for in-line recovery of up to 600 kg/hour of thermoformed skeleton.

Extrusion Machinery

- At Chinaplas 2017, German machine manufacturer Windmöller & Hölscher (W&H) will be presenting innovations in the field of film production as well as sack concepts such as film sack AD proFilm MP, which is characterised by high moisture protection. The Optimex blown film line for the production of film for further processing on the AD Plastic 2 for the newly developed AD proFilm MP-Sack is also a focus, a solution said to ensure high performance, according to the film recipe.

- According to Michael Fischer, CEO W&H

Asia Pacific, “The need for new innovative

quality forms for special fields of application

is increasing. This applies, for example, in

the production of breathable diaper film.”

With W&H’s Varex II three-layer system, with

inline-MDO stretching unit, it offers a machine

configuration for the production of a particularly

thin breathable diaper back sheet film

of only 12 g/sq m - a product that is

predominantly produced in cast film

extrusion and with a higher weight.

Thus, it says that blown films will

replace cast films for this application.

thin breathable diaper back sheet film

of only 12 g/sq m - a product that is

predominantly produced in cast film

extrusion and with a higher weight.

Thus, it says that blown films will

replace cast films for this application. - Meanwhile, load securing is also increasing in significance in Asia. With the Filmex II cast film extrusion line, W&H offers a machine solution for the manufacturing of demanding stretch films.

- As for woven PP bag production, W&H Machinery (formerly known as BSW Machinery) offers the new Convertex CL 140, said to exceed the speed of all other bottomers for cross bottom bags on the market. The first machine installed last year is said to “be successfully producing 140 units of 65-g woven PP cement bags/minute 24 hours a day.” The CL 140 has been geared for extra low bag weights, says the company.

- W&H also developed the LS (Lighter & Stronger) technology, whereby high quality PP tapes with tenacity up to 7 g/den and indexed micro-perforation provide the tools to be able to produce, for eg, cement bags with a weight of 65 g instead of the current global market standard of 80 g.

- During Chinaplas, W&H is offering visitors the option of a visit to its customer Weiyi in Guangzhou that has several Convertex plants in operation.

- Austrian extrusion machinery maker SML is to

commission its widest-ever CPP film line this

year, after the launch of the MasterCast, the world’s widest stretch wrap film line with an end

film width of 6,000 mm. With this concept, SML

says it has responded to the market demand for

increased film width and line output. Accordingly,

the new line, which will mainly produce CPP film

for metallising and laminating applications, will

have a trimmed final film width of 5,200 mm.

film width of 6,000 mm. With this concept, SML

says it has responded to the market demand for

increased film width and line output. Accordingly,

the new line, which will mainly produce CPP film

for metallising and laminating applications, will

have a trimmed final film width of 5,200 mm. - Apart from high output of 2,300 kg/hour, advantages include the low volume ratio of edge trim, compared to smaller lines, and reduced labour costs, since no additional personnel is required. Moreover, the kW/kg power consumption requirement is less. Therefore, this line concept has been developed for the economical production of large quantities, says SML.

- The extruder consists of a main 180/33 extruder and four 90/33 co-extruders. In addition to the feedblock, a three-layer, 5,700-mm width multi-manifold flat die is employed, which offers the advantage that the sealing and adhesive layers for metallisation can be closely controlled, allowing for accurate single layer distribution. The latter also means that the costs of special raw materials can be reduced.

- For easy cleaning, the multi-manifold die is mounted on a die splitting unit, which allows all four die parts to be opened and cleaned without removing the die. Moreover, in order to enhance the optical properties, the film is fixed onto the chill roll by means of a twin-chamber vacuum box, electrostatic edge pinners and a soft box, which allows chilled air to be blown onto the film.

- The first chill roll in the cooling and takeoff unit has a diameter of 1,200 mm, while the second has a diameter of 600 mm. Each of them is separately driven and cooled and SML’s threeroll design is used for the surface cleaning of the first chill roll. The entire cooling and take-off unit can be moved in both a horizontal and vertical direction and this allows finding the best possible casting position.

- The film produced is prepared for metallising or printing by a corona treatment station with a cooled and driven silicon treatment roll. The maximum generator power installed is 60 kW and the post-cooling roll is integrated with the treatment station to reduce the film web length. The edge trims, which are cut off upstream of the treatment station and a second time on the winder, are returned to the main extruder via a vertical scraptruder.

- The CPP line is equipped with the new W6000 turret winder, designed for wide CPP lines with final film widths of between 3,500 and 6,000 mm. The compact winder consists of an inlet section and right and left turret units.

- A spreader roller and a satellite roller are installed upstream of the winding station, making it possible to influence the air entrapment between the single film layers. The winder can operate in both the contact or gap winding mode. During roll changes, cross-cutting is carried out by an electrically activated flying knife and the film is attached to the new winding pipe electrostatically, avoiding the need for adhesive tape and saving manpower. Depending on the end film width, the winder employs 10 in. or 12 in. steel winding pipes, facilitated by an overhead crane.

- The winder can deal with 1,300-mm diameter rolls and a maximum roll weight of 7,000 kg, which is around 60,000 m length of 20-micron CPP film. The large winding diameter is an advantage for the metallising process because it increases the running time and cuts the metalliser set-up period.

- Austria-headquartered machinery maker Battenfeld-cincinnati China says it exports 30% of its output per year. “In 2016, our order intake increased by 35% compared to 2015. For 2017, we have a good order backlog and the new year has also brought in several large new orders, particularly for PO pipe equipment,” said CEO Toni Bernards.

- At Chinaplas, a solEX 60-40-C extruder for PO pipe production will be exhibited. The firm recently sold a 2.6-m diameter pipe line to South Korea and, last year, another 2.5 m line was sold to an Indian customer.

- Also at Chinaplas, a LeanEX C1-60-30 extruder will be shown. Since their introduction eight years ago, around 110 LeanEX extruders and 140 LeanEX turnkey pipe extrusion lines have been sold. In 2015, the company extended the LeanEX portfolio with 630 mm lines for larger pipe sizes

- Meanwhile, it will display the new BCtouch UX control, introduced last year at the K show. It will be displayed on the solEX 60-40-C extruder and also as a mobile operator terminal.

- US firm Processing Technologies International (PTi) says it has entered the high-speed extruder segment with the launch of its Super-G model for the processing of PP and high-impact polystyrene (HIPS) for the packaging market. The SGHS3000 is said to deliver improved melt quality as a result of the new lobe screw technology and is integrated with configurable roll stands. Two models, running at 1,000 and 1,200 rpms, are offered and PTi establishes the maximum rated speed based on an upper motor load threshold of 85%. The extruders also boast an oversized feed section for up to +70% regrind feed, along with a streamlined feed hopper, feed screw removal out-the-back of the unit, an easy-cleanout vent chamber, and linear bearing barrel glide support (patent pending).

- Nordson Corporation’s new, patent-pending design for dual or multilayer versions of its Premier and Ultracoat fluid coating dies is said to make it easier to achieve parallel alignment of the lip faces, for maintaining uniform, defect-free coating and preventing impingement of the lips against the roll. It, thus, makes it easier for web converters to achieve cost savings and productivity benefits by applying multiple fluids in a single pass.

- Whereas previously operators made changes to the die gap and the wet film thickness of the coating by inserting thin metal strips, or offset shims, between the dies and at the rear of the die, now operators need not require complicated calculations to determine which shim thickness closely achieves lip face parallelism.

- Nordson says it has achieved the new improvement by reconfiguring the die bodies of multi-layer Premier and Ultracoat systems so that the offset blocks, where the offset shims are inserted, are now in the same plane as the lip face. With the new design, the accuracy of the offset adjustment is independent of body shim thickness.

Home | Terms & Conditions | Privacy Policy | Contact | Webmail | Site Map

Copyright (c) 2017 www.plasticsandrubberasia.com. All rights reserved.